-

METALLURGICAL MACHINERY

In metallurgical machinery, oil mist lubrication systems are commonly used for lubrication of high-speed, heavy-duty, and large equipment, such as support roller bearings for strip mills, work and support roller bearings for four roll cold mills, and rolling guides for high-speed wire mills. These devices have high lubrication requirements, and oil mist lubrication can effectively meet their needs.

-

PETROCHEMICAL INDUSTRY

In the petrochemical industry, oil mist lubrication systems are used for lubrication of various mechanical equipment, such as compressors, pumps, fans, etc. These devices need to maintain efficient and stable operation during operation, and oil mist lubrication can ensure long-term stable operation of the equipment.

-

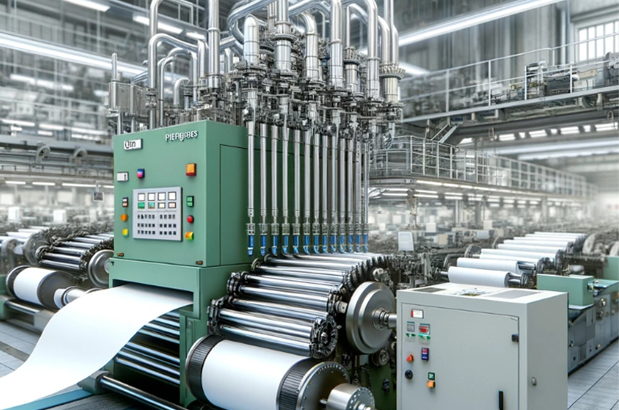

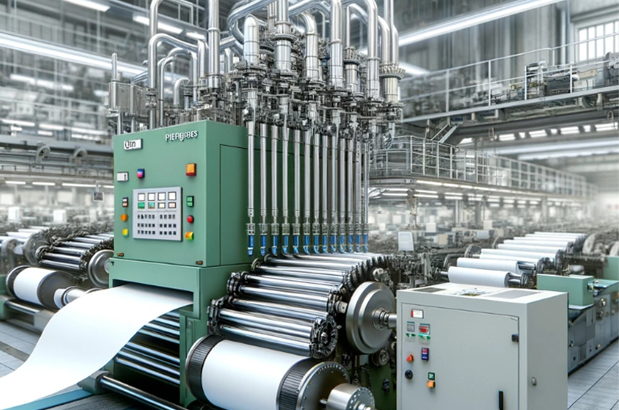

PAPER INDUSTRY

In the paper industry, oil mist lubrication systems are widely used in lubrication points such as bearings, gears, and chains of paper machines. Paper machines require high-speed and continuous operation during operation, and oil mist lubrication can ensure that these components receive sufficient lubrication and cooling.

-

TEXTILE INDUSTRY

High speed rotating components in textile machinery, such as spindles and rollers, are often lubricated using oil mist lubrication systems. This lubrication method can ensure that textile machinery maintains low friction and wear during high-speed operation, thereby improving production efficiency and product quality.

-

FOOD PROCESSING

In the food processing industry, oil mist lubrication systems are used on some mechanical equipment that requires strict hygiene requirements. Due to the precise control of the amount of lubricating oil and the absence of excessive oil leakage during use, the oil mist lubrication system can meet the hygiene requirements of the food processing industry.

-

OTHER INDUSTRIES

In addition to the aforementioned industries, oil mist lubrication systems are also widely used in various fields such as mechanical processing, electricity, mining, and building materials. In these fields, oil mist lubrication systems can exert their unique lubrication and cooling effects, providing guarantees for the stable operation of equipment.

METALLURGICAL MACHINERY

In metallurgical machinery, oil mist lubrication systems are commonly used for lubrication of high-speed, heavy-duty, and large equipment, such as support roller bearings for strip mills, work and support roller bearings for four roll cold mills, and rolling guides for high-speed wire mills. These devices have high lubrication requirements, and oil mist lubrication can effectively meet their needs.

PETROCHEMICAL INDUSTRY

In the petrochemical industry, oil mist lubrication systems are used for lubrication of various mechanical equipment, such as compressors, pumps, fans, etc. These devices need to maintain efficient and stable operation during operation, and oil mist lubrication can ensure long-term stable operation of the equipment.

PAPER INDUSTRY

In the paper industry, oil mist lubrication systems are widely used in lubrication points such as bearings, gears, and chains of paper machines. Paper machines require high-speed and continuous operation during operation, and oil mist lubrication can ensure that these components receive sufficient lubrication and cooling.

TEXTILE INDUSTRY

High speed rotating components in textile machinery, such as spindles and rollers, are often lubricated using oil mist lubrication systems. This lubrication method can ensure that textile machinery maintains low friction and wear during high-speed operation, thereby improving production efficiency and product quality.

FOOD PROCESSING

In the food processing industry, oil mist lubrication systems are used on some mechanical equipment that requires strict hygiene requirements. Due to the precise control of the amount of lubricating oil and the absence of excessive oil leakage during use, the oil mist lubrication system can meet the hygiene requirements of the food processing industry.

OTHER INDUSTRIES

In addition to the aforementioned industries, oil mist lubrication systems are also widely used in various fields such as mechanical processing, electricity, mining, and building materials. In these fields, oil mist lubrication systems can exert their unique lubrication and cooling effects, providing guarantees for the stable operation of equipment.